What plastics are considered difficult to machine?

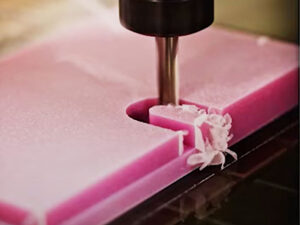

With so many variations of high performance and advanced engineering plastics, it can be difficult to know which ones require more attention and precision when machining them into finished parts. Even basic plastic formulations can present challenges with machines. In this article we will discuss important parameters and environmental recommendations that can be used to successfully machine difficult plastic materials. Some examples of these materials are G10, FR4, GPO, phenolic laminates, as well as glass, molybdenum disulfide, and carbon filled; Ultem, PEEK, Nylon, UHMW, PPS, and Polycarbonate.

Parameters

Here are some recommended parameters to keep in mind before machining complex, intricate, and difficult plastics.

- Ensure you have read and understand the factory guidelines on the recommended tools, blades, collets, feeds and speeds for machining the material specified. These recommendations range from different machine processes such as a CNC mill, CNC lathe, CNC panel saw, CNC router, press brake, and oven to name a few.

- Most factories have machining guides and/or recommendations on how to machine the plastics they make. This information is typically available upon request.

Environment

Plastics differ from common alloys in the way they respond to chemicals and coolants when being machined. It usually recommended to machine plastics in a dry environment, without coolants or liquids. The benefits of this are:

- Improved tool life

- Reduced chip evacuation issues

- Cleaner working environment

It can be recommended in some instances to use coolants, but this due to specific material parameters, such as when heat generation is a concern, or when a smooth finish is required. You can refer to the factory recommendations in such instances.

Another important, and sometimes overlooked, aspect of environment concerns with plastics is having appropriate ventilation and dust collection. Some difficult plastics can have irritating odors or glass fibers. With proper ventilation and adequate dust collection, this can often times be mitigated.

It can be a challenge to machine or fabricate plastics. However, taking the time to research the plastic’s machining recommendations and environmental suggestions, you can mitigate potential risks and problems. Machining difficult plastics can be a great addition to any machining or fabrication business’s service offering and add top and bottom-line success.